Boring Heads / 180.XXX

Boring Heads / 180.XXX

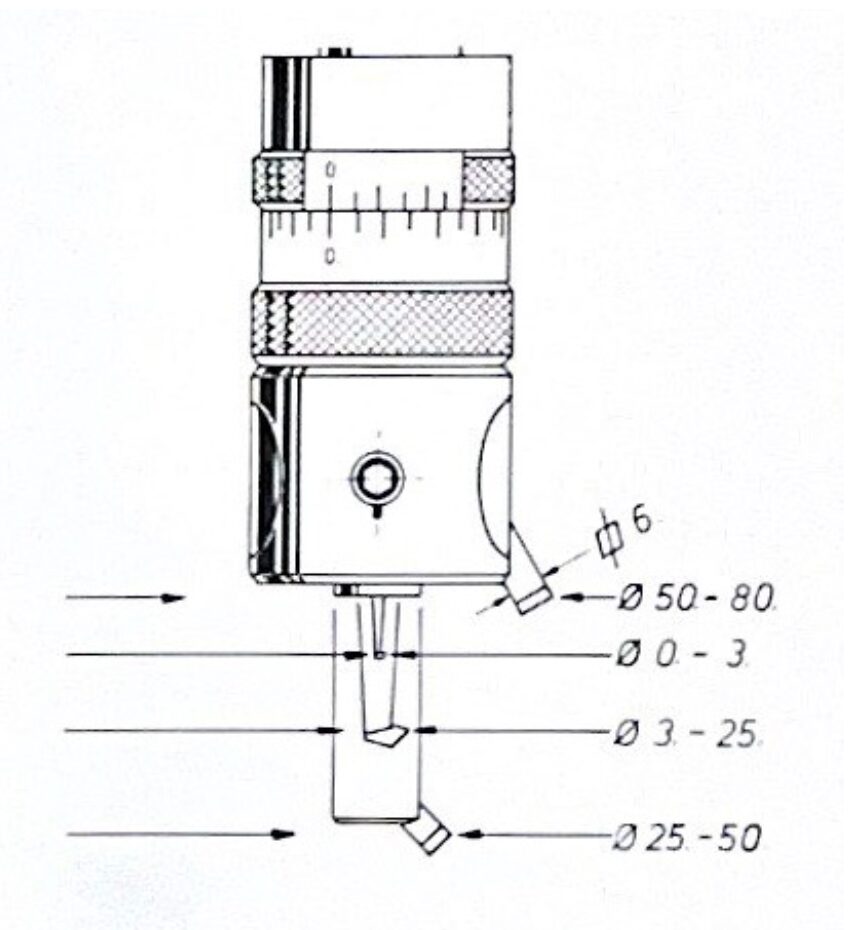

•Machining capacity: 0-80 mm

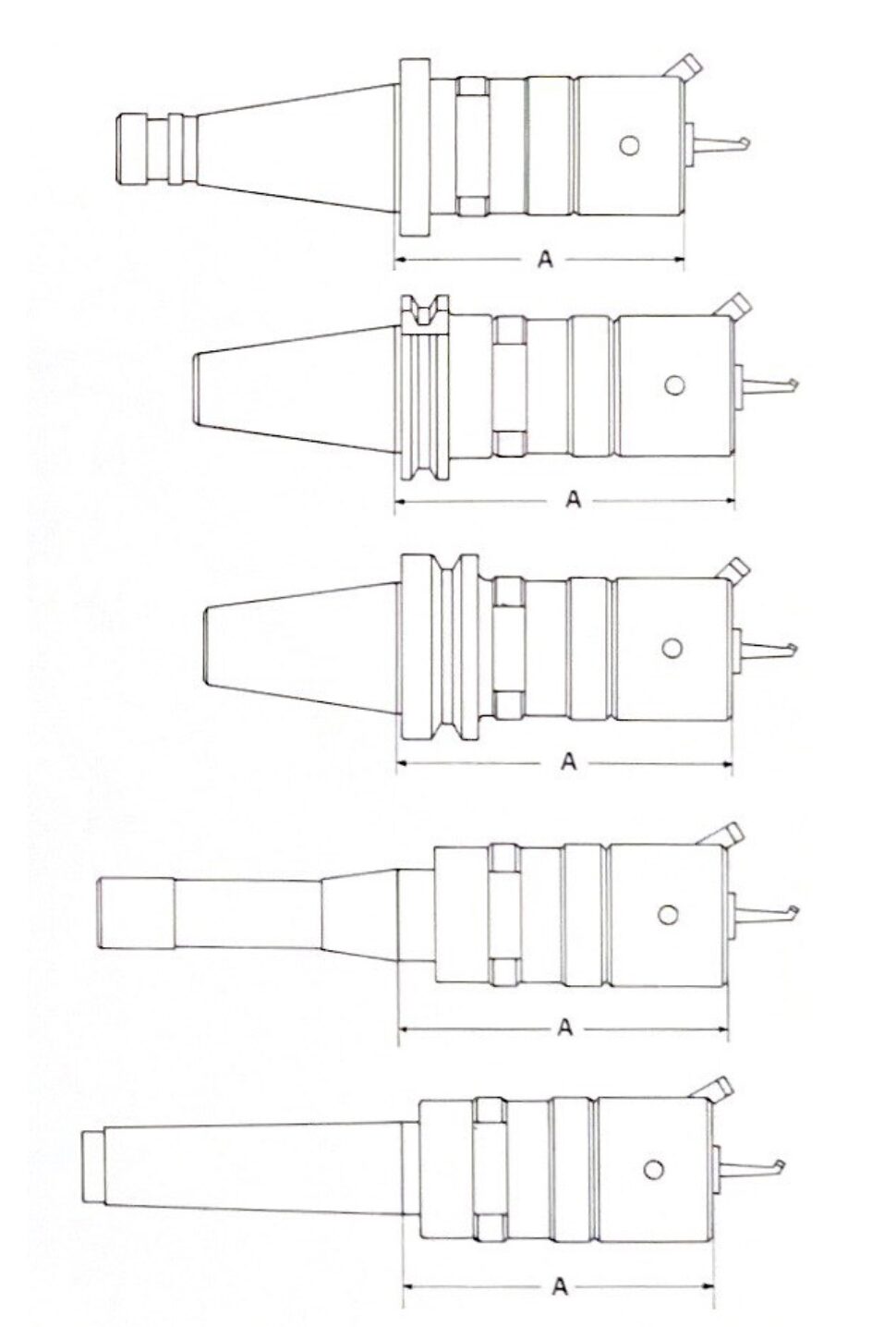

•Fixed shank (coupling)

•Manufactured for Morse taper 3-4 (DIN 228-A)

•Manufactured for ISO taper 30-40-50 (DIN 2080)

•Manufactured for ISO taper 40-45-50 (DIN 69871/1)

•Manufactured for ISO taper 40-45-50 (DIN MAS 403-BT)

•Manufactured for R-8 taper (Bridgeport)

•Vernier reading precision of 5 µm in Ø

•One full turn of the vernier equals 2 mm in Ø

•One division equals 50 µm in Ø

•Travel: 10 mm

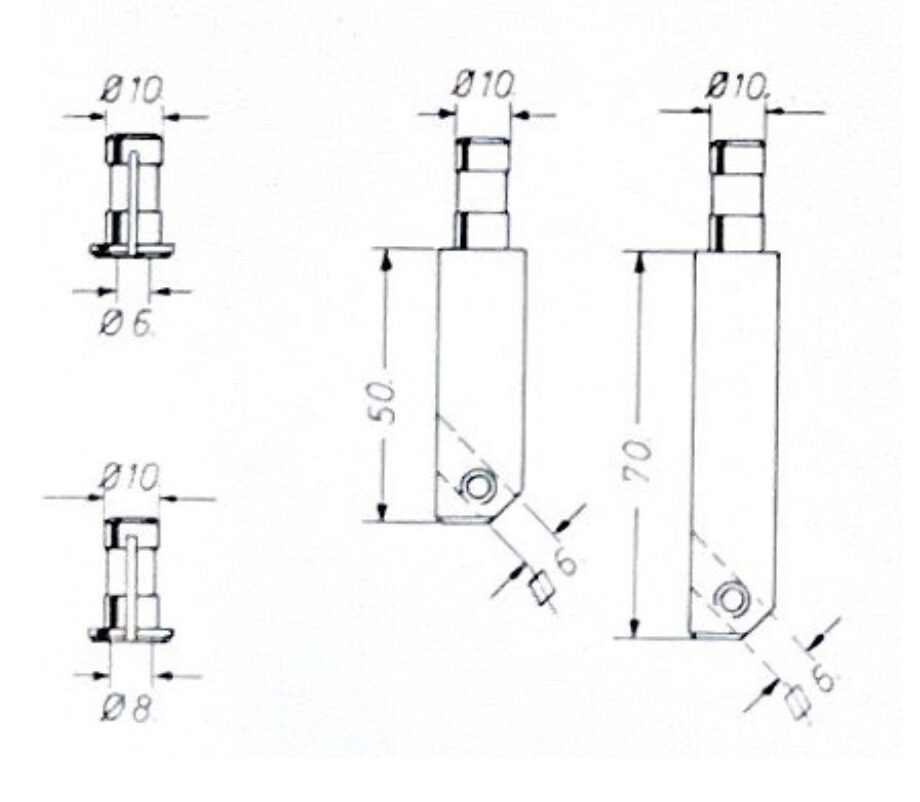

•Delivered in a wooden box with two hex keys, two collets, and two boring bars

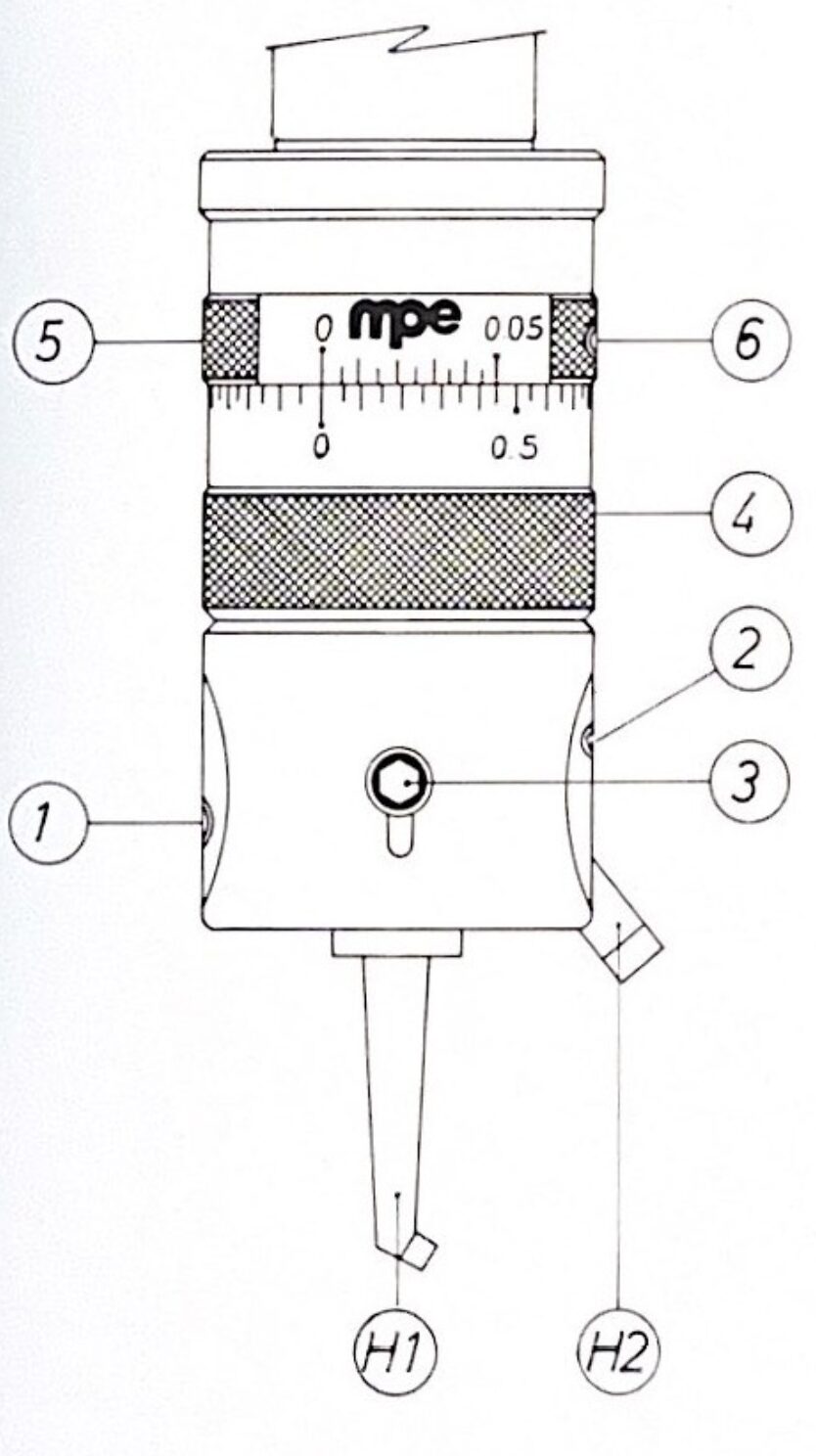

Designed for precise machining of internal diameters from 0 to 80 mm. The carriage has two tool seats: one central seat (H1 tool) for boring diameters up to 50 mm and another lateral seat (H2 tool) for diameters from 50 to 80 mm.

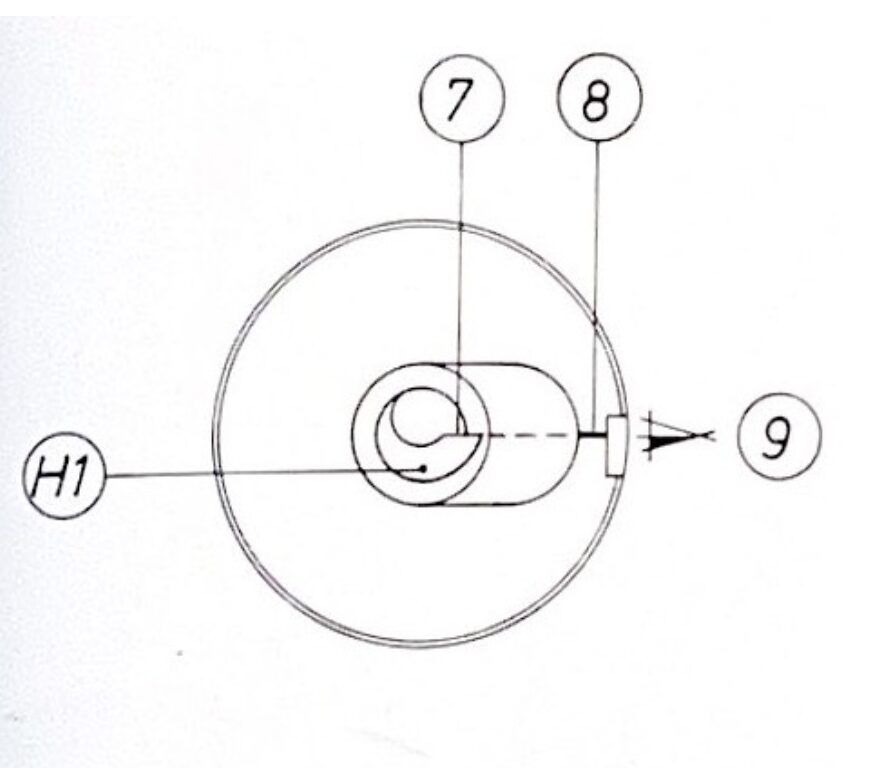

This head must always rotate to the right (clockwise) to advance in the indicated direction (no. 9).

When mounting H1 or H2 tools, alignment between their cutting edge (no. 7) and the orientation mark (no. 8) is crucial. The H1 tools are locked with the screw (no. 1) and the H2 tools with screw (no. 2).

For micrometric adjustment of the boring tool, it is recommended to:

The screw (no. 1) should tighten the boring bars and collets exactly 90° from their full cut.

Refer to our catalog for more details on the head.